Precision Engineered: Our Wire Harness Manufacturing Process

Good day! valued clients and partners.

As the Manager of XMKEHAN Wire Harness Solutions, I'm proud to outline the meticulous production process at the heart of our operations. We understand that a wire harness is the nervous system of your equipment, and its reliability is paramount. Therefore, we've built a rigorous, efficient, and quality-centric manufacturing system, ensuring every harness we deliver is absolutely reliable and performs exceptionally.

Our process strictly adheres to industry best practices and decades of experience, focusing on these critical stages:

-

Precision Foundation: Sub-Assembly Fabrication & Inspection

-

Core Principle: Dimensions Dictated by the Assembly Board. When creating each sub-assembly (component wire set), the sole reference for cutting wire lengths is the assembly board drawing. We eliminate waste and rework by ensuring sub-assemblies conform perfectly to the final assembly requirements, not just their individual drawings.

-

Dual Assurance: Every completed sub-assembly undergoes stringent 100% Electrical Testing (continuity) and 100% Full Visual Inspection (appearance, dimensions, etc.). This guarantees defect-free components as the foundation for assembly.

-

Goal: Zero dimensional deviation. Zero incoming defects.

-

-

Structured Assembly: Harness Routing & Layout

-

Zoned & Sequential Operation: Routing is systematic. Operators meticulously place inspected sub-assemblies flat onto the assembly board per drawings, following a strict "Zone First, Cross-Zone Second" methodology: completing all sub-assemblies within one defined zone before placing those spanning multiple zones.

-

Complexity Gradation: Even cross-zone wires are placed "Simple Before Complex" to maximize clarity, minimize errors, and avoid interference.

-

Goal: Precise routing, clear paths, interference-free layout.

-

-

Secure Integration: Pin Insertion & Tying

-

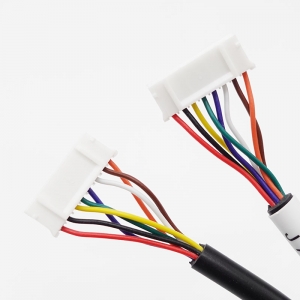

Reliable Connections: All terminals (TER) must be inserted accurately into their designated connectors (CONN, D-SUB, IDC, HOUSING). Pre-insertion of specific TERs occurs where required by design.

-

Professional Tying:

-

Precise Placement: Tie locations strictly follow assembly board markings. Starts are typically at designated double-wire points.

-

Consistent Craftsmanship: Ties must be evenly spaced (~25mm apart), with secure knots (square knots at start/end), and controlled tail lengths (~10mm). Cable ties must be tightened with tails trimmed ≤1mm.

-

Damage Prevention: Strict protocols prohibit looping/pulling wires via connectors or excessive force during tying. Wires are secured before tying to absolutely prevent terminal pull-out, broken strands, or wire damage. Tying materials must never damage wire insulation. Wire bundles must lie parallel and immobile, with conductors neither twisted nor over-tensioned.

-

-

Goal: Secure connections, neat/firm/undamaged bundle arrangement.

-

-

The Quality Bastion: 100% Electrical Testing

-

Authoritative Data: Harness complexity demands absolute accuracy in test programs. Our testing protocols undergo rigorous dual verification and sign-off by Production Engineering (PE) and Quality Engineering (QE) before execution.

-

Comprehensive Check: Every single assembled harness must pass this critical test, guaranteeing 100% circuit continuity, zero shorts, zero opens, zero miswires. This is our non-negotiable standard for functional integrity.

-

Goal: Zero electrical defects.

-

-

Eagle-Eyed Scrutiny: Final Quality Control (QC)

-

Post-testing, dedicated QC inspectors perform a comprehensive final check, focusing on:

-

Terminal and Connector (CONN) position within specified tolerance zones.

-

Tie consistency, appearance, and adherence to specifications.

-

Correct assembly methods for all components (tubes, seals, boots, etc.).

-

Overall harness parallelism, stability, and compliance with all process requirements.

-

-

Goal: Flawless appearance, structure, and craftsmanship.

-

-

The Quality Passport: Storage & Delivery

-

Only harnesses passing stringent Outgoing Quality Control (OQC) are approved for warehousing and subsequent packing/shipment.

-

We provide complete Safety & Quality Certificates with each delivery, ensuring full traceability.

-

Goal: Delivery of products that meet or exceed requirements, validated through multiple checkpoints.

-

Our Unwavering Quality Commitment:

-

Standards-Driven: We rigorously follow customer specifications and maintain ISO 9001:2015 certification, ensuring documented, auditable processes at every step.

-

Relentless Precision: "Meticulous attention to detail and continuous improvement" is our operational creed, from sub-assembly to final packing. We pursue zero defects.

-

Assured Reliability: The physical integrity (undamaged, secure) and electrical safety (100% continuity, no shorts/opens) of our harnesses are our core promises.

At XMKEHAN, we don't just manufacture wire harnesses; we engineer precision nervous systems for your critical applications. Through our disciplined process, skilled craftsmanship, and uncompromising dedication to quality, we provide robust, stable, and utterly dependable wire harness solutions. Partner with us for confidence delivered.

Thank you. We welcome the opportunity to host you for a facility tour to witness our quality processes firsthand.